Catch Can Tests

Designed to test how well the pivot is applying water evenly across the paddock and get insight into how well the machine is doing its job

The test incorporates all the available metrics of the pivot simultaneously recorded with measured application depth to capture what the parts of the pivot are each doing.The result is a set of data that shows:

> How evenly the pivot is applying water to the field

> is the water meter working properly

> are there any pressure or flow issues

> is the pump operating properly

> etc, etc> Results presented in a report

Recent work with Dairy SA and Dairy Australia has shown most pivots tested were not applying water as well as the owners thought. Measured improvements are made as a result of identifying problems in how the machine operates. This results in higher productivity and lower operating costs.

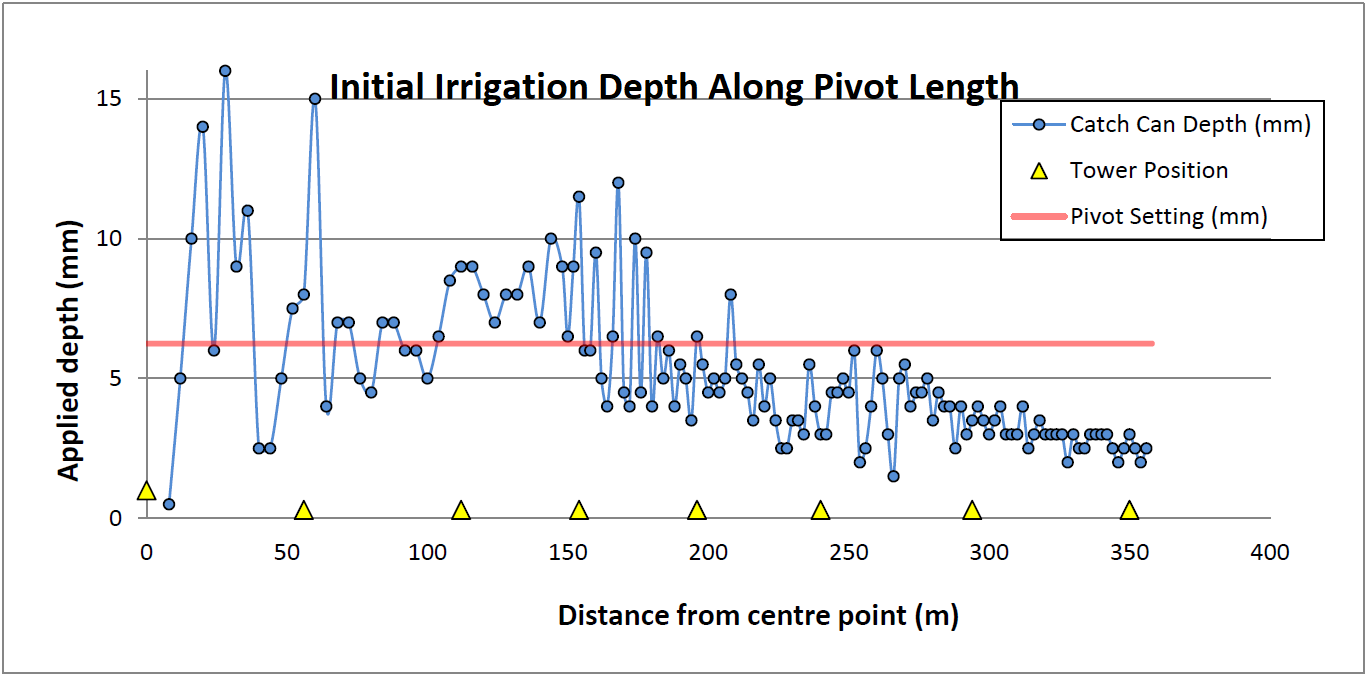

Pivot "looked" to be operating correctly

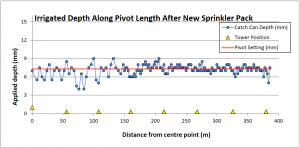

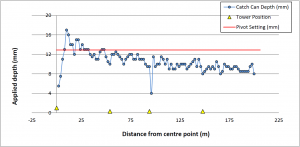

Pattern of application depth

The depth of water applied to the field along the length of the pivot is highly variable, showing issues with both the age of the sprinklers and low line pressure